Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Basic knowledge of knitted clothing processing

Release time:

2024-03-28

Source:

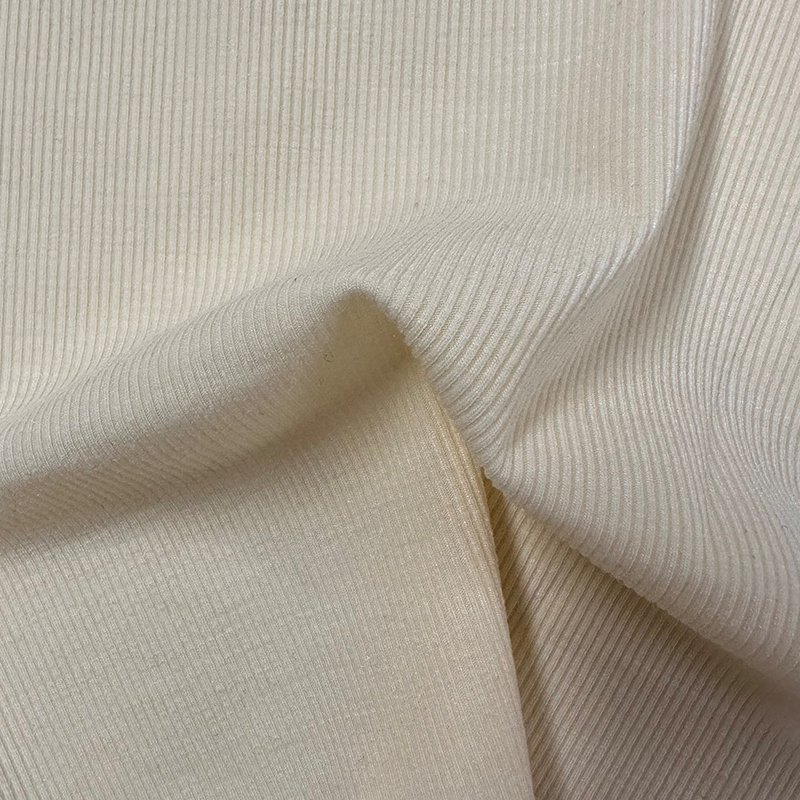

Knitted clothes are mostly made of cotton and chemical fiber cotton yarn, which are characterized by softness, elasticity, breathability, sweat absorption and comfort, such as Sportswear and underwear. Knitted clothing as clothing not only has commonalities with woven clothing, but also has its own characteristics.

During the process of selecting the drill, the first thing to look at is the appearance

Process flow:

Spinning → weaving → fabric inspection → cutting → sewing → ironing → inspection

(1) Spinning

The purpose of spinning is to wind the cotton yarn entering the factory into a certain structure and specification of rolled packages, suitable for knitting production. During the spinning process, it is necessary to eliminate some defects on the yarn while maintaining a certain uniform tension. Necessary auxiliary treatments such as waxing and oiling should be carried out on the yarn to improve its weaving performance, production efficiency, and product quality.

(2) Weaving

Weaving is the process of weaving yarn into rolls and interweaving them into fabric through a loom. This is also the fundamental difference between knitted and woven clothing.

The weaving methods can be divided into two categories: weft knitting and warp knitting, and most of the fabrics used for knitted clothing are weft knitted fabrics. Weft knitting is the process of feeding one or more yarns from the weft direction into the working needles of a knitting machine, causing the yarns to be sequentially bent into loops and then strung together to form a weft knitted fabric. The machine used to weave this type of knitted fabric is called a weft knitting machine. Weft knitting has great adaptability to the variety of yarns and Linear density, and the variety of knitted fabrics produced is also very wide. There are a wide variety of weft knitted fabrics, which can be woven into various fabrics for both inner and outer clothing, as well as into single or partially formed products. At the same time, the process and machine structure of weft knitting are relatively simple, easy to operate, and the production efficiency of the machine is relatively high. Therefore, weft knitting has a large proportion in the knitting industry. There are many types of weft knitting machines, which are generally distinguished by the number of needle beds, the form of needle beds, and the type of needle used. Warp knitting is a process in which one or several sets of parallel yarns are arranged on a knitting needle and woven longitudinally. The machine used to weave this type of knitted fabric is called a warp knitting machine. Generally, warp knitted fabrics have less detachment and elongation than weft knitted fabrics, and have better stability in structure and appearance. They have a wide range of applications, including producing clothing fabrics, mosquito nets, curtains, lace decorative fabrics, medical fabrics, etc. Warp knitting machines can also be distinguished by needle beds and needle types.

(3) Fabric inspection

As the quality of grey cloth is directly related to the quality and output of finished products, before cutting, the number of pieces, size, density, batch number and Linear density must be checked to see if they meet the requirements according to the cutting cloth ingredient list. When inspecting the cloth, the grey cloth shall be inspected one by one according to the standards. All kinds of defects affecting the quality of finished products, such as color, stitch leakage, holes, oil stains, must be marked and recorded.

(4) Cropping

The main process of cutting knitted clothing:

Broken material → Borrowing defects → Marking → Cutting → Binding.

Borrowing defects is an important part of improving product quality and saving materials. During the cutting process, try to borrow the defects on the fabric to the cutting or stitching area as much as possible.

Knitted fabrics are cut according to the meridional mesh auxiliary materials, and the cutting method is generally used, including flat sets, mutual sets, inlay sets, splicing sets, and slit sets.

The following precautions should be taken when cutting knitted fabrics:

(1) Do not use folding marks and printed edges on obvious parts of clothing.

(2) Do not use tapered hole markings in cutting to avoid affecting the appearance of the garment.

(5) Sewing

The existing sewing processes and equipment in China's knitting industry are mainly based on sewing machine models such as medium and high speed flat sewing machines (commonly known as "flat cars"), medium and high speed overlock sewing machines (commonly known as "koke cars"), and stretch sewing machines.

Due to the fact that knitted fabrics are made up of a series of loops, the edges of the cut pieces are prone to detachment. Therefore, the edges of the pieces should be covered and sewn (commonly known as "edge stitching") before being processed using a flat sewing machine or other sewing techniques. Flat and overlock sewing machines are the main types of machines used for sewing knitted fashion.

During the sewing process, it is generally important to grasp the following key points.

1. Seams. Due to the characteristics of longitudinal and transverse extensibility (i.e. elasticity) of knitted fabrics, as well as the disadvantage of easy detachment of edge coils, the stitching of knitted fashion should meet the following requirements:

(1) The seam should have stretchability and strength that are compatible with the knitted fabric.

(2) The seam should be able to prevent the detachment of the fabric coil.

(3) Properly control the density of the seam. For example, the stitch density of the flat sewing machine for thick fabrics is controlled at 9-10 stitches/2cm, the stitch density of the overlock sewing machine is 6-7 stitches/2cm, the stitch density of the flat sewing machine for thin fabrics is controlled at 10-11 stitches/2cm, and the stitch density of the overlock sewing machine is 7-8 stitches/2cm.

2. Sewing thread. Generally, 9.8tex is used for pure cotton knitted fabric × 4 or 7.4tex × 3% pure cotton and polyester cotton blended yarn, with 7.8tex chemical fiber knitted fabric × 2% stretch nylon yarn and 5tex × 6 nylon threads. The suture should meet the following quality requirements:

(1) Pure cotton thread (sewing thread) used in sewing machines should be combed cotton thread, which has high strength and uniformity.

(2) The sewing thread should have a certain degree of elasticity to prevent breakage during the sewing process due to the twisting or squeezing of the thread.

(3) The stitching must have softness.

(4) The stitching must be uniform and smooth, reducing resistance or friction in the thread slot and needle hole, and avoiding defects such as broken threads and uneven stitch tension.

3. Sewing needles. Sewing machine needles are also known as sewing needles or machine needles. In order to achieve the ideal fit between the sewing needle and the sewing material and thread, it is necessary to choose a suitable sewing needle.

(6) Ironing

Knitted clothing is ironed to achieve a smooth appearance and accurate size. When ironing, insert a lining board inside the garment to maintain a certain shape and specification of the product. The size of the lining board is slightly larger than the required size of the garment to prevent it from shrinking and becoming too small. The temperature of ironing is generally controlled between 180 ℃ and 200 ℃, which is safer and less prone to yellowing and coking.

(7) Finished product inspection

Finished product inspection is a comprehensive inspection of products before leaving the factory, including two major items: appearance quality and internal quality. The appearance inspection content includes dimensional tolerance, appearance defects, seam fastness, etc. The internal testing items include fabric weight per unit area, color fastness, shrinkage rate, etc.

Previous

Previous

Related News

2025-08-21 19:00

Why Nylon Wool Fabric is the Future of Sustainable Apparel

Why Nylon Wool Fabric is the Future of Sustainable Apparel Table of Contents 1. Introduction to Sustainable Apparel and Its Importance 2. Understanding Nylon Wool Fabric: A Comprehensive Overview 3. Environmental Benefits of Nylon Wool Fabric 3.1 Reduced Resource Consumption 3.2 Lower Carbon Footprint 4. Durability and Longevity: A Wise Investment 5. Versatility in Fashion Design 6. The Growing Po

2025-08-11 18:40

The Versatility and Benefits of Wool Fabric in Textile Industry

Wool fabric, derived from the fleece of sheep, is renowned for its unique properties that make it a highly sought-after material in the textile industry. Unlike synthetic fibers, wool is a natural fiber that possesses a range of advantages, contributing to its enduring popularity among designers and manufacturers. One of the most significant attributes of wool fabric is its excellent thermal regul