Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Mastering the Art of Jersey Merino Wool Fabric: A Comprehensive Guide to the Manufacturing Process

Release time:

2024-10-06

Source:

Understanding the Manufacturing Process of Jersey Merino Wool Fabric

Table of Contents

- 1. Introduction to Jersey Merino Wool Fabric

- 2. What is Merino Wool?

- 3. Key Characteristics of Jersey Merino Wool Fabric

- 4. Sourcing and Sorting of Merino Wool

- 5. The Spinning Process of Merino Wool

- 6. Weaving and Knitting Techniques

- 7. Dyeing and Finishing Jersey Merino Wool Fabric

- 8. Applications of Jersey Merino Wool Fabric

- 9. Sustainability in Merino Wool Production

- 10. Conclusion

- 11. FAQs

1. Introduction to Jersey Merino Wool Fabric

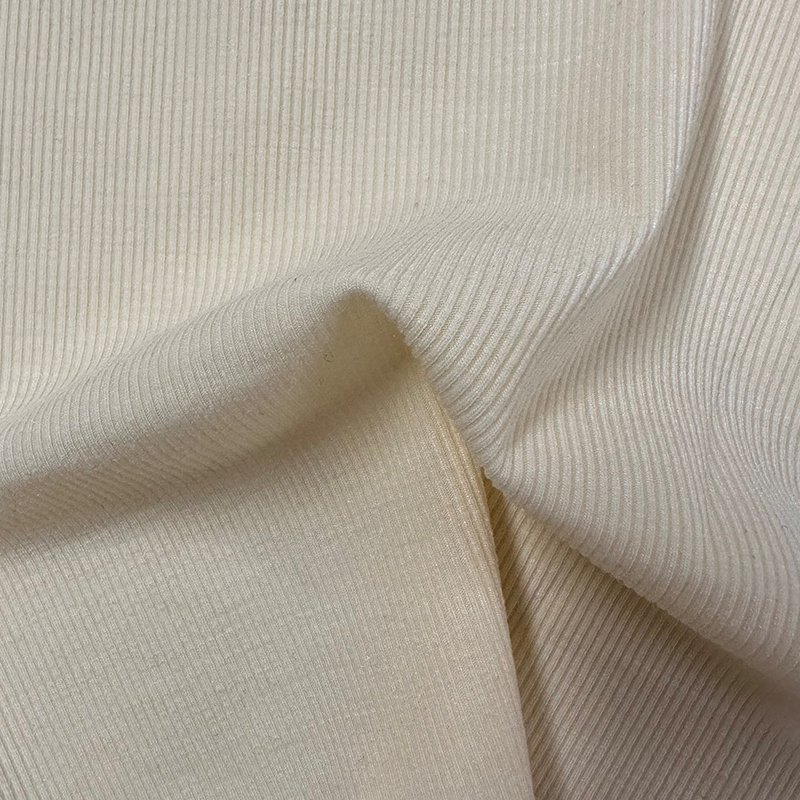

Jersey Merino wool fabric has gained immense popularity in the textile industry due to its unique properties and versatility. This fabric is celebrated for its softness, breathability, and natural moisture-wicking capabilities. Understanding the manufacturing process is crucial for appreciating the craftsmanship behind this esteemed material. In this article, we will explore the intricate steps involved in producing Jersey Merino wool fabric, providing insights into quality control and sustainable practices.

2. What is Merino Wool?

Merino wool comes from the Merino sheep, a breed known for producing fine, soft wool that excels in temperature regulation. Unlike traditional wool, Merino wool fibers are incredibly fine, measuring between 17 to 22 microns in diameter. This fineness contributes to the luxurious feel of the fabric, making it suitable for both casual and formal wear. Additionally, Merino wool has natural elasticity, which helps maintain the shape of garments over time.

2.1 Benefits of Merino Wool

The benefits of Merino wool extend beyond its softness. Here are some key advantages:

- **Moisture Management**: Merino wool can absorb up to 30% of its weight in moisture without feeling wet, keeping the wearer comfortable.

- **Breathability**: The fabric allows for excellent airflow, which prevents overheating during physical activities.

- **Odor Resistance**: Natural lanolin in the wool helps reduce odor buildup, making it ideal for activewear.

- **Thermal Regulation**: The natural crimp in the wool fibers provides insulation, keeping the wearer warm in cold weather while remaining cool in warmer conditions.

3. Key Characteristics of Jersey Merino Wool Fabric

Jersey Merino wool fabric is distinguished by several unique characteristics:

- **Softness**: The fabric’s fine fibers provide an exceptionally soft touch, reducing the likelihood of itchiness associated with coarser wool.

- **Stretch**: The knitted structure of jersey allows for stretch in multiple directions, ensuring comfort and ease of movement.

- **Durability**: High-quality Merino wool is resilient and can withstand regular wear and tear, making it a long-lasting choice.

- **Versatility**: Jersey Merino wool can be used for a variety of garments, including t-shirts, sweaters, and activewear.

4. Sourcing and Sorting of Merino Wool

The journey of Jersey Merino wool fabric begins with sourcing the finest Merino wool. This process involves several steps:

4.1 Selecting Quality Raw Wool

Producers often source wool from specific regions renowned for their Merino sheep, such as Australia and New Zealand. Wool from these regions is known for its superior quality and fiber fineness.

4.2 Wool Sorting

Once the raw wool is harvested, it undergoes sorting. Wool sorting is an essential step where the fleece is separated based on fiber diameter, length, and quality. This ensures that only the best fibers are used in the manufacturing process.

5. The Spinning Process of Merino Wool

After sorting, the next step is the spinning process, which transforms the raw wool into yarn.

5.1 Preparation for Spinning

The sorted wool is first cleaned and carded to remove any impurities and to align the fibers. This preparation helps create a uniform yarn.

5.2 Spinning Techniques

There are various spinning techniques used, but the most common methods for producing Jersey Merino wool yarn include:

- **Ring Spinning**: This traditional spinning technique produces strong and fine yarns ideal for high-quality fabrics.

- **Open-End Spinning**: A more modern technique, suitable for producing bulkier yarns.

The choice of spinning technique can affect the final texture and strength of the fabric.

6. Weaving and Knitting Techniques

Jersey Merino wool fabric is primarily produced using knitting techniques, which contribute to its stretch and softness.

6.1 Knitting Methods

The most common knitting methods for Jersey fabric include:

- **Single Jersey Knitting**: This technique creates a fabric with a smooth face and a slightly rough back, making it lightweight and ideal for t-shirts.

- **Double Jersey Knitting**: This method produces a thicker fabric, often used for warmer garments and offering superior durability.

6.2 Importance of Gauge

The gauge used during knitting determines the fabric's thickness and density. A finer gauge results in a lighter fabric, whereas a thicker gauge yields a heavier, more robust material.

7. Dyeing and Finishing Jersey Merino Wool Fabric

Dyeing and finishing are critical steps in enhancing the aesthetic appeal and functionality of Jersey Merino wool fabric.

7.1 Dyeing Techniques

Various dyeing techniques can be employed, including:

- **Reactive Dyeing**: This method creates vibrant colors with excellent wash-fastness.

- **Natural Dyeing**: For those seeking eco-friendly options, natural dyes derived from plants and minerals are used.

7.2 Finishing Processes

Finishing processes such as softening, anti-pilling treatments, and water repellency applications enhance the performance characteristics of the fabric. These treatments contribute to improved durability and user comfort.

8. Applications of Jersey Merino Wool Fabric

Jersey Merino wool fabric is favored in various applications due to its unique properties:

8.1 Clothing

Jersey Merino wool is commonly used in making:

- **Activewear**: Its moisture-wicking properties make it ideal for sports and outdoor activities.

- **Casual Wear**: T-shirts, dresses, and casual tops often utilize this fabric for comfort and style.

- **Layering**: Lightweight and breathable, it serves as an excellent base layer for colder climates.

8.2 Home Textiles

Beyond clothing, Jersey Merino wool is also used for:

- **Blankets and Throws**: The softness and warmth of the fabric make it perfect for cozy home textiles.

- **Upholstery**: Its durability allows for use in furniture fabrics.

9. Sustainability in Merino Wool Production

Sustainability is becoming increasingly important in the textile industry, and Merino wool production is no exception.

9.1 Eco-Friendly Practices

Merino wool is a renewable resource, and many producers are adopting eco-friendly practices such as:

- **Responsible Farming**: Ensuring sheep are raised in humane conditions and maintaining land health.

- **Water Conservation**: Utilizing techniques that minimize water usage during cultivation and processing.

9.2 Certifications and Standards

Look for certifications such as the Responsible Wool Standard (RWS), which guarantees that wool comes from farms that practice sustainable farming and uphold animal welfare.

10. Conclusion

The manufacturing process of Jersey Merino wool fabric is a blend of traditional craftsmanship and modern technology. Understanding each step, from sourcing and sorting to spinning, knitting, dyeing, and finishing, allows for a greater appreciation of this exquisite fabric. As consumers become more aware of sustainability, choosing Jersey Merino wool fabric becomes not just a style choice but a mindful decision that aligns with eco-friendly practices. Embracing this fabric means investing in quality, comfort, and sustainability, making Jersey Merino wool a timeless addition to any wardrobe.

11. FAQs

What makes Jersey Merino wool different from regular wool?

Jersey Merino wool is softer, finer, and more breathable than regular wool, making it more comfortable against the skin.

How should I care for Jersey Merino wool garments?

It is recommended to hand wash or use a gentle cycle in cold water with a mild detergent, followed by laying flat to dry.

Is Merino wool sustainable?

Yes, Merino wool is a renewable resource, and with responsible farming practices, it can be sustainably produced.

Can Jersey Merino wool be used for activewear?

Absolutely! Its moisture-wicking and breathable properties make it ideal for activewear and outdoor clothing.

What are the best uses for Jersey Merino wool fabric?

Jersey Merino wool is versatile and can be used for t-shirts, sweaters, blankets, and even upholstery, among other applications.

jersey merino wool fabric oem

Related News

2025-08-21 19:00

Why Nylon Wool Fabric is the Future of Sustainable Apparel

Why Nylon Wool Fabric is the Future of Sustainable Apparel Table of Contents 1. Introduction to Sustainable Apparel and Its Importance 2. Understanding Nylon Wool Fabric: A Comprehensive Overview 3. Environmental Benefits of Nylon Wool Fabric 3.1 Reduced Resource Consumption 3.2 Lower Carbon Footprint 4. Durability and Longevity: A Wise Investment 5. Versatility in Fashion Design 6. The Growing Po

2025-08-11 18:40

The Versatility and Benefits of Wool Fabric in Textile Industry

Wool fabric, derived from the fleece of sheep, is renowned for its unique properties that make it a highly sought-after material in the textile industry. Unlike synthetic fibers, wool is a natural fiber that possesses a range of advantages, contributing to its enduring popularity among designers and manufacturers. One of the most significant attributes of wool fabric is its excellent thermal regul