Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

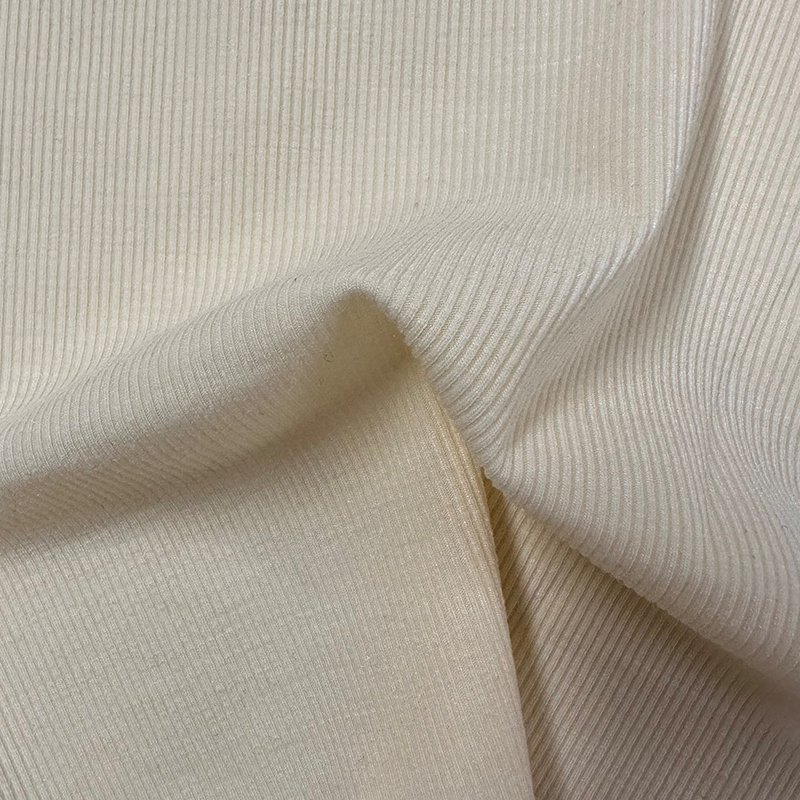

Understanding Wool Insulation Fabric Spots: A Guide for Functional Textile Professionals

Release time:

2024-12-04

Source:

Firstly, it’s important to recognize that wool is a naturally occurring fiber renowned for its superior insulation properties. These properties stem from the unique structure of wool fibers, which trap air and provide excellent thermal resistance. However, in manufacturing and processing, spots may develop due to a variety of factors including uneven dye application, moisture retention during production, or natural irregularities within the wool itself.

To mitigate the appearance of wool insulation fabric spots, manufacturers can adopt several strategies. One effective method is to ensure uniform processing conditions during the dyeing and finishing stages. Utilizing advanced dyeing techniques, such as continuous dyeing or digital printing, can help achieve consistent coloration and minimize the occurrence of spots.

Moreover, proper wool handling during manufacturing is crucial. Wool fibers should be treated gently to prevent felting, which can lead to uneven insulation. Implementing quality control measures at every stage of production can help identify problem areas early, allowing for corrective actions that maintain the integrity of the fabric.

In terms of practical applications, understanding and managing wool insulation fabric spots can influence product performance. For instance, in outdoor apparel or insulation products, any variation in fabric consistency can affect thermal regulation and moisture management. Therefore, manufacturers should consider how these spots might impact the end-use of the textile and adjust their production processes accordingly.

Additionally, educating customers on the nature of wool insulation fabric spots can enhance their appreciation of the product. Providing clear information about the benefits of wool, such as its breathability and natural moisture-wicking properties, can help counter any concerns related to aesthetic imperfections.

Finally, ongoing research and development in the field of functional textiles can lead to innovative solutions for addressing wool insulation fabric spots. Exploring new treatments, blends, or technologies may yield fabrics that not only minimize spots but also enhance overall performance.

In conclusion, while wool insulation fabric spots may pose challenges, a comprehensive understanding and strategic approach can transform these challenges into opportunities. By focusing on quality control, education, and innovation, professionals in the functional textile industry can ensure that their products meet performance standards while maximizing the unique benefits of wool.

wool insulation fabric spots

Related News

2025-08-21 19:00

Why Nylon Wool Fabric is the Future of Sustainable Apparel

Why Nylon Wool Fabric is the Future of Sustainable Apparel Table of Contents 1. Introduction to Sustainable Apparel and Its Importance 2. Understanding Nylon Wool Fabric: A Comprehensive Overview 3. Environmental Benefits of Nylon Wool Fabric 3.1 Reduced Resource Consumption 3.2 Lower Carbon Footprint 4. Durability and Longevity: A Wise Investment 5. Versatility in Fashion Design 6. The Growing Po

2025-08-11 18:40

The Versatility and Benefits of Wool Fabric in Textile Industry

Wool fabric, derived from the fleece of sheep, is renowned for its unique properties that make it a highly sought-after material in the textile industry. Unlike synthetic fibers, wool is a natural fiber that possesses a range of advantages, contributing to its enduring popularity among designers and manufacturers. One of the most significant attributes of wool fabric is its excellent thermal regul